Exhaust Gaskets FAQs

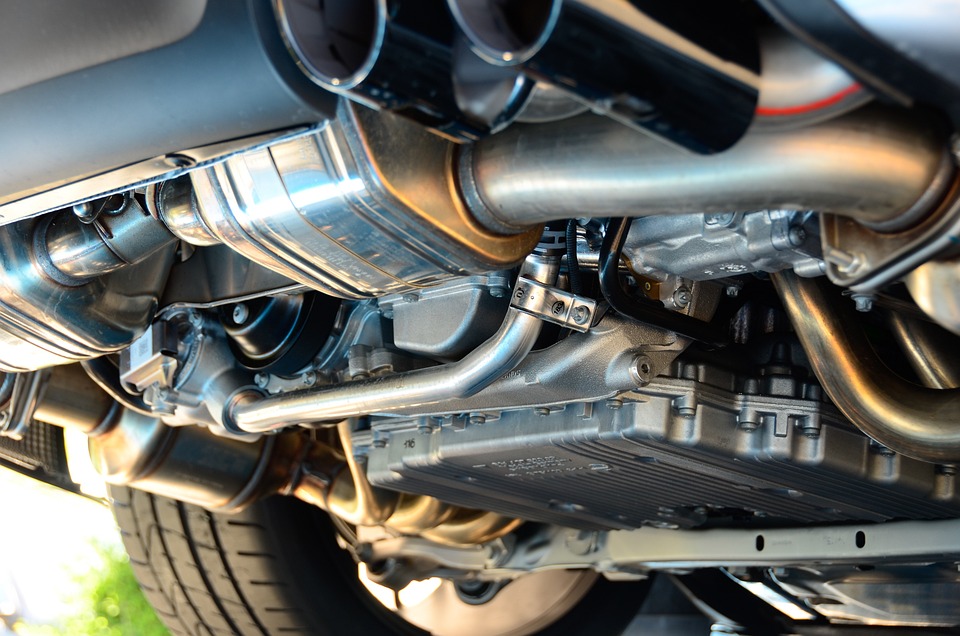

Exhaust gaskets are designed to provide a tight seal, which prevents exhaust gases from leaking and reduces noise levels. Additionally, they can provide added strength to an exhaust system, help protect against abrasion damage and keep engine temperatures in check.

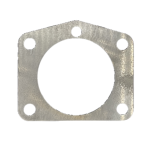

Depending on the vehicle, it is recommended that an exhaust gasket be replaced every 50,000-100,000 miles or every other oil change for optimal performance.

Exhaust gaskets can be made from a variety of materials including rubber, metal and multi-layered steel composites depending on the application.

Driving with a damaged or worn out exhaust gasket can cause harmful fumes to enter the passenger compartment and can also lead to further damage if left unchecked. It’s best to replace your gasket as soon as possible for safety reasons.

Yes! Different vehicles require specific types of exhaust gaskets depending on their design and function requirements such as flat versus molded seals and stainless steel versus graphite seals.

With the right tools and knowledge, installing an exhaust gasket yourself is achievable but may require advanced automotive repair experience for a proper installation. If you’re uncertain about your skillset it’s best to leave this job to a professional mechanic for better results.