Types of Rubber Gaskets and Seals

Rubber Gaskets and seals can be made in a wide variety of shapes and styles. The most common gaskets are round and can be supplied with or without holes. These are typically used for sealing two flanges.

Styles of Gaskets

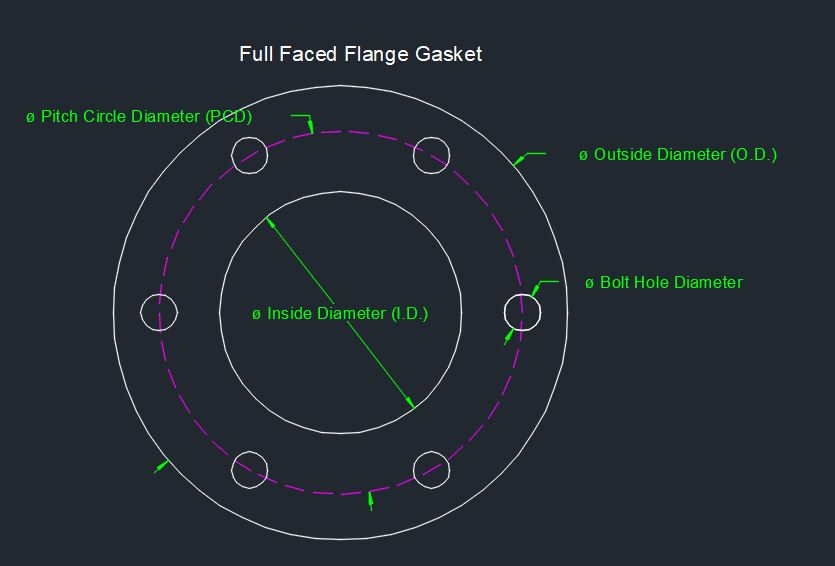

If gaskets have holes for the flanges bolts to go through, they are called full faced gaskets. Gaskets without holes are referred to as inner bolt circle gaskets (IBC), washers or stub gaskets.

The position of the holes for the bolts in full faced gaskets, is referred to as either PCD (Pitch Circle Diameter) or BCD (Bolt Circle Diameter.)

Standard Table Gaskets

Many rubber gaskets are made to sizes published in standard gasket tables. These are lists of gasket sizes suitable for different sizes of pipelines, or flanges, with different pressure ratings.

The most common standard tables are BS EN 12560 which superseded BS 1560, ASME B16.21, BS10 1962 and BS EN 1514-2:2014.

We also manufacture many different variations of standard table gaskets, like the examples below, ensuring that you get exactly the right seal.

The Mickey Mouse gasket on the left is called that as the bolt holes resemble the famous mouse’s ears.

These types of gasket fit inside the bolt circle, utilising just 2 of the bolts, for locating the gasket.

Similarly, the 1 1/2″ ASA 150 tabbed gasket on the right locates by a single bolt hole, and the extended tab makes it easier to fit in tight spaces or harsh environments such as undersea pipelines.

The gasket in the middle, is a 65mm PN16 blanking gasket. This would be used to seal flanges off if there is no requirement for liquids or air to pass through.

To ensure the quickest production times for you, we have around 15,000 different cutting formes meaning we can produce your parts quickly.

Custom Rubber Seals and Gaskets

For bespoke and custom gasket requirements, our teams accrued knowledge, of over 100 years, mean you are in safe hands. We will work with your drawings, samples or designs to develop the best seal for your application.

We utilise 3 state of the art CAD programmes to produce accurate drawings to ensure compliance.

Our experience in working with almost every polymer means we can recommend exactly the right rubber for your seals.

Other Gasket Shapes and Styles

As mentioned above, gaskets can be produced in almost any shape. We stock a huge polymer range in roll form to ensure we can supply rubber seals quickly and economically.

If you require a specialist grade of rubber which is not available in roll form, or you require a gasket which is not flat, we have extensive moulding capabilities.

In our moulding shop we can produce moulded sheets or finished, moulded gaskets.

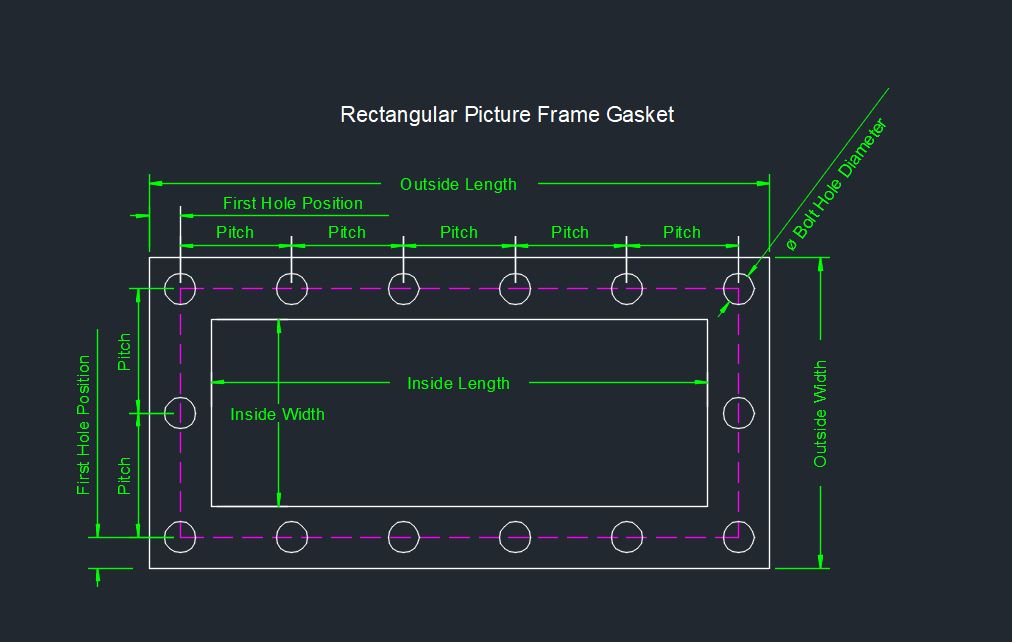

Rectangular gaskets are referred to as “picture frame gaskets“.

The full-faced gasket in the middle has holes for bolts to go through to join 2 flanges.

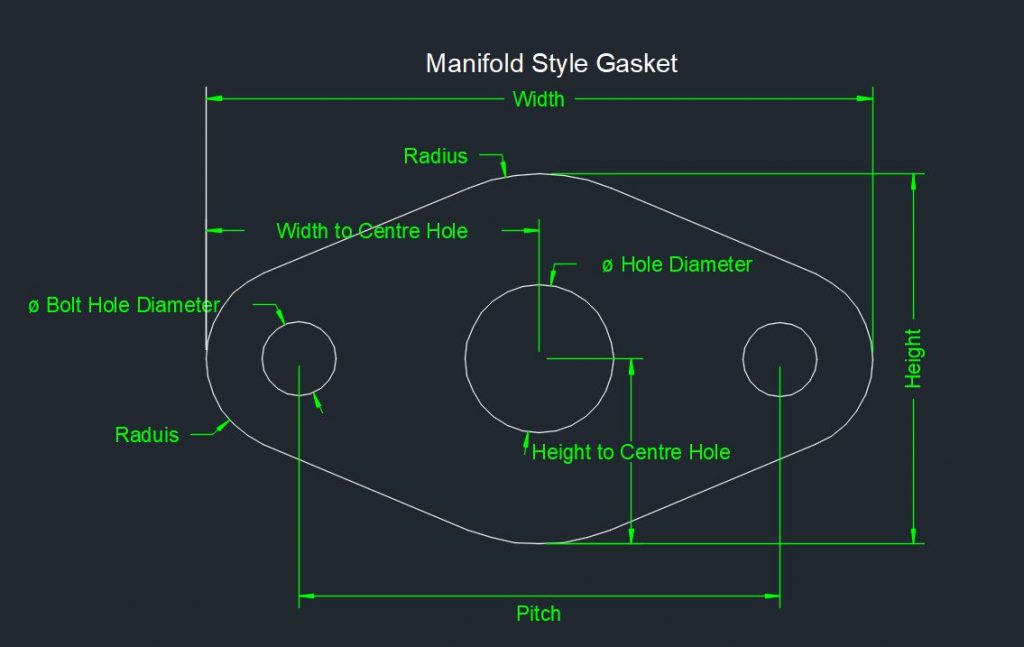

The last diagram shows a manifold style gasket.

Why would we mould rubber seals and gaskets?

This is because most sealing requirements are for flat gaskets or washers, to seal uneven surfaces like on pipe flanges. Sometimes, however, you may require a gasket that pushes into a recess, like a pipe. The two photo’s above show how a moulded rubber gasket may look.

In instances like this a flat gasket wouldn’t be suitable so this is where our mould shop comes into the equation.

Another circumstance that crops up frequently is when either a high priced polymer is required, or if calendared rubber sheeting is not available.

With high priced materials like fluoroelastomers, Aflas and fluoro-silicones, the biggest cost can potentially be the waste from the centre of the gasket. Fortunately we have a range of ring moulds, meaning we can mould a ring then cut the flat gasket out of it so minimising waste.

You may have a requirement for a specific grade of rubber manufactured into flat gaskets. It could involve DTD grades, different colours or hardness’s. We have a range of sheet moulds which enable us to produce sheets to then cut into gaskets and seals.

We have more information on our rubber mouldings service here.

Related articles

If you need any help or advice simply give us a call or fill in the enquiry form and one of our technical team will help you out.